A mechanical fuel pump is a device that supplies fuel to the engine of a vehicle by using mechanical force. It is an essential component of the fuel delivery system in many internal combustion engines.

The pump draws fuel from the fuel tank and delivers it to the carburetor or fuel injectors, ensuring proper fuel flow and pressure for engine operation. Without a functioning fuel pump, the engine may not receive the fuel it needs to run efficiently or at all.

Regular maintenance and inspection of the fuel pump are important to prevent potential issues and maintain the overall performance of the vehicle.

The Basics Of Mechanical Fuel Pump

Working Principle

A mechanical fuel pump is a crucial component in a vehicle’s fuel system that delivers fuel from the gas tank to the engine. It operates using a simple but effective mechanism.

Components

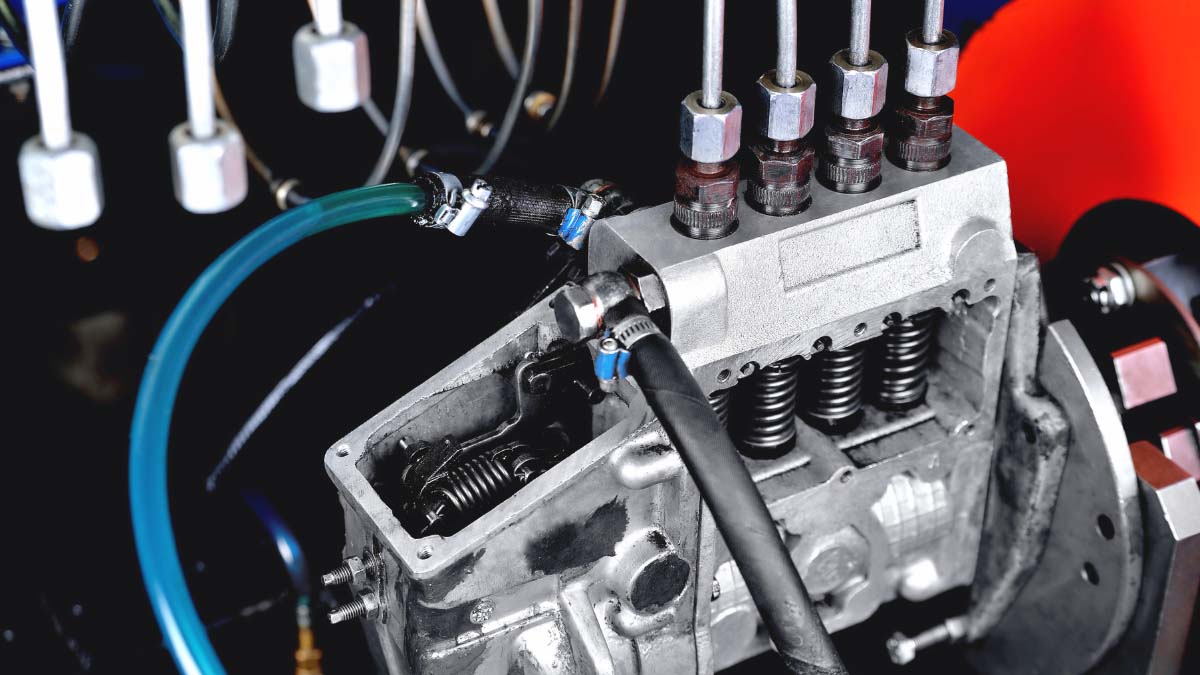

The key components of a fuel pump include the pump body, diaphragm, inlet and outlet valves, and lever mechanism. These work together to create a reliable fuel delivery system.

Advantages Of Mechanical Fuel Pump

When it comes to fuel delivery in vehicles, mechanical fuel pumps play a crucial role. These pumps offer several advantages that contribute to the smooth functioning of an engine. In this post, we will explore three key advantages of mechanical fuel pumps, namely reliability, consistency in performance, and ease of maintenance.

Reliability

Mechanical fuel pumps are known for their exceptional reliability. Unlike electrical fuel pumps that rely on the vehicle’s electrical system, mechanical fuel pumps are mechanical devices that work independently of the electrical system. This means that even in situations where the vehicle’s battery fails or there are electrical malfunctions, the mechanical fuel pump can continue delivering fuel to the engine.

Mechanical fuel pumps are especially reliable in off-road vehicles and in remote locations where access to electrical power may be limited. Their simplicity and independence from the electrical system make them a preferred choice for many vehicle owners and enthusiasts.

Consistency In Performance

One of the key advantages of mechanical fuel pumps is their consistency in performance. These pumps maintain a steady flow of fuel to the engine, ensuring optimal combustion and power delivery. The mechanical design of these pumps allows them to maintain a constant pressure and flow rate, regardless of engine speed or load.

This consistency in performance translates into improved engine efficiency and fuel economy. It also contributes to a smoother driving experience and reduced emissions. Whether you’re driving at high speeds on the highway or crawling through rough terrain, a mechanical fuel pump ensures that your engine receives the fuel it needs to perform at its best.

Ease Of Maintenance

Having the ability to easily maintain and service a component is crucial for vehicle owners and mechanics. Mechanical fuel pumps offer this advantage with their simple design and uncomplicated construction. These pumps are less prone to failure and require minimal maintenance compared to their electrical counterparts.

In the event of a malfunction, troubleshooting and repairing a mechanical fuel pump is relatively straightforward. Their mechanical nature allows for easy access and replacement of worn-out components. This not only saves time but also reduces the overall maintenance costs associated with keeping a vehicle’s fuel system in optimal condition.

Mechanical fuel pumps offer several advantages that make them a reliable and preferred choice for many vehicle owners. Their reliability, consistency in performance, and ease of maintenance contribute to the smooth functioning of the engine and enhance the overall driving experience. Whether you’re off-roading or going for a long drive, a mechanical fuel pump ensures that your vehicle’s engine receives a continuous supply of fuel, allowing it to perform at its best.

Key Features To Look For

When looking for a mechanical fuel pump, it’s essential to consider key features that ensure optimal performance and reliability. By understanding the key attributes to look for, you can make an informed decision that meets your specific requirements.

Here are the crucial features to consider when evaluating mechanical fuel pumps:

Durability

Durability is a critical aspect to consider when selecting a mechanical fuel pump. A durable pump will withstand the rigors of continual usage and maintain consistent performance over an extended period. Look for pumps constructed from high-quality materials such as stainless steel or aluminum, which offer excellent resistance to corrosion and wear. Additionally, consider sealing integrity to ensure the pump is resistant to leaks and environmental contaminants, enhancing its longevity.

Efficiency

Efficiency is paramount for ensuring optimal fuel delivery and engine performance. A high-performing pump will efficiently supply fuel to the engine, maximizing combustion and power output. Look for pumps with precise metering capabilities that deliver fuel consistently and accurately. Additionally, consider pumps with minimal friction and smooth operation, as these features contribute to overall efficiency and reduce energy wastage.

Comparing Mechanical Fuel Pump To Electric Fuel Pump

When it comes to fuel delivery systems, the debate between mechanical fuel pumps and electric fuel pumps has been a longstanding one. Each type of pump has its own advantages and drawbacks, and understanding the differences can help vehicle owners make informed decisions about their fuel delivery systems.

Performance

In terms of performance, mechanical fuel pumps are known for their reliability and consistent fuel delivery. These pumps operate in sync with the engine’s revolutions, providing a steady flow of fuel without being affected by electrical system issues. On the other hand, electric fuel pumps can be more efficient in delivering fuel at higher pressures, making them a popular choice for high-performance vehicles and modern fuel injection systems.

Maintenance

Maintenance for mechanical fuel pumps is relatively straightforward as they have fewer components and are less prone to electrical malfunctions. However, the mechanical nature of these pumps means they can wear out over time and may require periodic adjustments. Electric fuel pumps, while generally reliable, may require more frequent monitoring due to their reliance on electrical connections and components.

Installing A Mechanical Fuel Pump

To install a mechanical fuel pump, start by disconnecting the negative battery cable. Next, remove the fuel lines and mounting bolts, then carefully extract the old pump. Install the new pump in reverse order, ensuring a secure fit. Finally, reconnect the battery cable and test the pump for proper operation.

Installing a mechanical fuel pump is a crucial step in ensuring the efficient functioning of your vehicle’s engine. A mechanical fuel pump is responsible for delivering a steady supply of fuel to the engine, ensuring proper combustion and optimal performance. By following a step-by-step guide and making adequate preparations, you can successfully install a mechanical fuel pump. Let’s dive into the process!

Preparation

Before beginning the installation process, it is important to gather the necessary tools and materials. Here’s a list of items you’ll need for a smooth installation: – A new mechanical fuel pump – Wrench set – Screwdriver – Clean rags or towels – Safety goggles – Work gloves Once you have all the required tools and materials, make sure you have a well-ventilated workspace, preferably outdoors or in a garage with good airflow. Safety should always be a top priority, so be sure to wear goggles and gloves throughout the installation process.

Step-by-step Guide

Follow these step-by-step instructions to install a mechanical fuel pump effectively:

- Begin by disconnecting the negative terminal of the vehicle’s battery. This precautionary measure ensures your safety and prevents any accidental sparks.

- Locate the current fuel pump on your vehicle. Depending on the make and model, it can be found on the engine block or the fuel tank. Refer to your vehicle’s manual if you’re unsure.

- Once you’ve located the fuel pump, use a wrench to disconnect the fuel lines connected to it. Make sure to place a rag or towel underneath to catch any fuel that may spill.

- Next, remove the mounting bolts that secure the old fuel pump. Keep track of these bolts as you’ll need them for the installation of the new pump.

- Carefully detach the old mechanical fuel pump from the engine or fuel tank, making sure not to damage any surrounding components.

- Clean the mounting area thoroughly to ensure a secure fit for the new fuel pump. Use a clean rag or towel to remove any dirt, debris, or remnants of the old pump.

- Take your new mechanical fuel pump and align it with the mounting area. Make sure it is positioned correctly to prevent any leaks or misalignments.

- Insert the mounting bolts into the designated holes and tighten them using a wrench. Ensure the fuel pump is securely fastened to the engine or fuel tank.

- Reconnect the fuel lines you disconnected earlier, using a wrench to tighten the fittings properly. Check for any signs of leakage before proceeding.

- Finally, reconnect the negative terminal of the vehicle’s battery. This restores power to the fuel pump and allows you to test its functionality.

With the installation complete, you can now start your vehicle and check for any fuel pump-related issues. If everything is in order, your mechanical fuel pump should supply the engine with a consistent flow of fuel, ensuring optimum performance.

Installing a mechanical fuel pump may seem daunting at first, but by following this step-by-step guide and taking the necessary precautions, you can successfully complete the process. With a properly installed fuel pump, your vehicle’s engine will operate smoothly, delivering the power and efficiency you desire.

Common Issues And Troubleshooting

Mechanical fuel pumps are essential components in a vehicle’s fuel system, ensuring the right amount of fuel reaches the engine efficiently. However, like any mechanical part, fuel pumps can encounter problems that may affect the performance of the vehicle. Understanding common issues and troubleshooting methods can help in maintaining the fuel pump’s functionality.

Low Fuel Pressure

Low fuel pressure in a mechanical fuel pump can lead to engine stalling or lack of power during acceleration. To address this issue, check for clogs in the fuel lines, replace any damaged fuel filters, and ensure the pump is delivering the correct pressure to the engine.

Leaks

Leaks in a mechanical fuel pump can cause fuel wastage and pose a fire hazard. Inspect the pump for any visible leaks, tighten connections securely, and replace any worn-out seals or gaskets to prevent further leakage.

Maintenance Tips For Longevity

For optimal performance and longevity of your mechanical fuel pump, it is crucial to routinely check for any leaks, ensure proper lubrication of moving parts, and change the fuel filter regularly to prevent clogs and maintain fuel flow. Additionally, avoid running the pump dry and keep it clean from debris or contaminants to extend its lifespan.

regular Inspections

Inspect the fuel pump visually for any signs of leaks or damage. Check the fuel lines and connections for tightness and wear. Have a professional technician perform a pressure test regularly.

cleaning

Regularly clean the exterior of the fuel pump to prevent dirt buildup. Use a mild detergent and water solution for cleaning. Inspect and clean the fuel filter to ensure proper fuel flow.

Upgrading Your Mechanical Fuel Pump

Are you looking to squeeze out every last drop of performance from your engine? Upgrading your mechanical fuel pump could be the game-changer you need. A mechanical fuel pump plays a crucial role in delivering fuel to your engine. By upgrading it, you can experience increased horsepower and enhanced fuel delivery, resulting in improved performance. Read on to discover how upgrading your mechanical fuel pump can take your engine’s performance to new heights.

Increased Horsepower

Your engine’s performance is directly connected to the amount of horsepower it generates. By upgrading your mechanical fuel pump, you can significantly increase the horsepower your engine produces. An upgraded fuel pump ensures a more efficient and consistent fuel supply, allowing your engine to generate more power. With increased horsepower, you can enjoy faster acceleration, higher top speeds, and an overall enhanced driving experience. It’s time to unleash the full potential of your engine by upgrading your mechanical fuel pump.

Enhanced Fuel Delivery

A reliable and consistent fuel delivery system is essential for optimal engine performance. By upgrading your mechanical fuel pump, you can enhance the fuel delivery to your engine. An upgraded fuel pump can provide a higher and more consistent volume of fuel, ensuring that your engine receives an ample supply at all times. This improved fuel delivery optimizes combustion, resulting in improved fuel efficiency and power output. With enhanced fuel delivery, you can experience smoother acceleration, improved throttle response, and a more efficient engine overall.

Performance Tuning With Mechanical Fuel Pump

When it comes to performance tuning with a mechanical fuel pump, one of the key factors to consider is optimizing for power. Upgrading your fuel pump can greatly enhance the power output of your engine, providing a noticeable boost in performance. To get the most out of your mechanical fuel pump, here are a few things to consider:

- Fuel Pressure Adjustment: Fine-tuning the fuel pressure can make a significant difference in power output. By increasing the pressure slightly, you can deliver a higher volume of fuel to the engine, resulting in improved acceleration and overall performance.

- Upgrading Fuel Lines: Ensuring that the fuel lines are properly sized and free from restrictions is essential for optimal power delivery. Consider upgrading to larger diameter lines and replacing any old or damaged components that may impede fuel flow.

- Pump Capacity: Selecting a mechanical fuel pump with a higher capacity can provide a steady and abundant fuel supply to the engine, especially during high-demand situations. This helps prevent fuel starvation and ensures consistent power delivery.

While power gains are undoubtedly important for many performance enthusiasts, it’s also crucial to consider fuel economy. Here are a few fuel economy considerations when tuning with a mechanical fuel pump:

- Efficiency Balance: Striking the right balance between power and fuel efficiency is key. A fuel pump that delivers excess fuel can lead to unnecessary consumption, resulting in decreased mileage. It’s important to optimize your fuel pump setup to provide adequate fuel without wastage.

- Proper Carburetor Setup: Ensuring the carburetor is properly adjusted and calibrated is crucial for optimal fuel economy. A rich fuel mixture can lead to increased fuel consumption, while a lean mixture may compromise power output. Fine-tuning your carburetor settings in conjunction with your mechanical fuel pump can help achieve the perfect balance between performance and efficiency.

- Regular Maintenance: Regularly maintaining and cleaning your mechanical fuel pump is essential for optimal performance and fuel economy. Over time, debris and contaminants can accumulate, affecting fuel flow and efficiency. Incorporating routine inspections and cleaning can help maximize fuel economy and prevent potential issues.

By considering these factors and making the necessary adjustments, you can effectively tune your mechanical fuel pump for both improved power and fuel economy.

Frequently Asked Questions For Mechanical Fuel Pump

What Is A Mechanical Fuel Pump?

A mechanical fuel pump is a device that delivers fuel from the gas tank to the carburetor.

How Does A Mechanical Fuel Pump Work?

A mechanical fuel pump operates by the reciprocating motion of a diaphragm or plunger.

What Are The Common Issues With Mechanical Fuel Pumps?

Common issues include blockages in the pump, wear on the diaphragm, and failure of the valves.

How Often Should A Mechanical Fuel Pump Be Replaced?

Mechanical fuel pumps should be replaced every 60,000 to 70,000 miles or as per manufacturer guidelines.

Can A Mechanical Fuel Pump Be Repaired Instead Of Replaced?

Yes, some mechanical fuel pump issues can be repaired by replacing specific worn or damaged components.

Conclusion

A mechanical fuel pump plays a crucial role in a vehicle’s proper functioning by delivering fuel from the tank to the engine. Its reliable and efficient operation ensures a steady flow of fuel, enhancing performance and fuel efficiency. With its durable design and easy maintenance, a mechanical fuel pump is a cost-effective choice for many vehicles.

So, next time you’re up for replacing or upgrading your fuel pump, consider the benefits of a mechanical fuel pump.